Building the Time Capsule: How We Protect Your Stories for 1000 Years

At sealed.love, we’re not just storing love stories. We’re building a vault meant to last a millennium. Here’s how our prototype stainless steel capsule works, how we protect M-Discs inside, and why this engineering matters for the future of your memories.

At sealed.love, our mission is to keep your stories alive for centuries. Family, art, pets, friendship, love. The emotional side is beautiful, but there is also a very real, very technical part: building a physical capsule that can protect your memories for at least 1000 years.

This is a prototype in active development. I’m improving the design daily. I’ll share photos and build notes along the way, including CNC machining shots and checks.

How the capsule is built

-

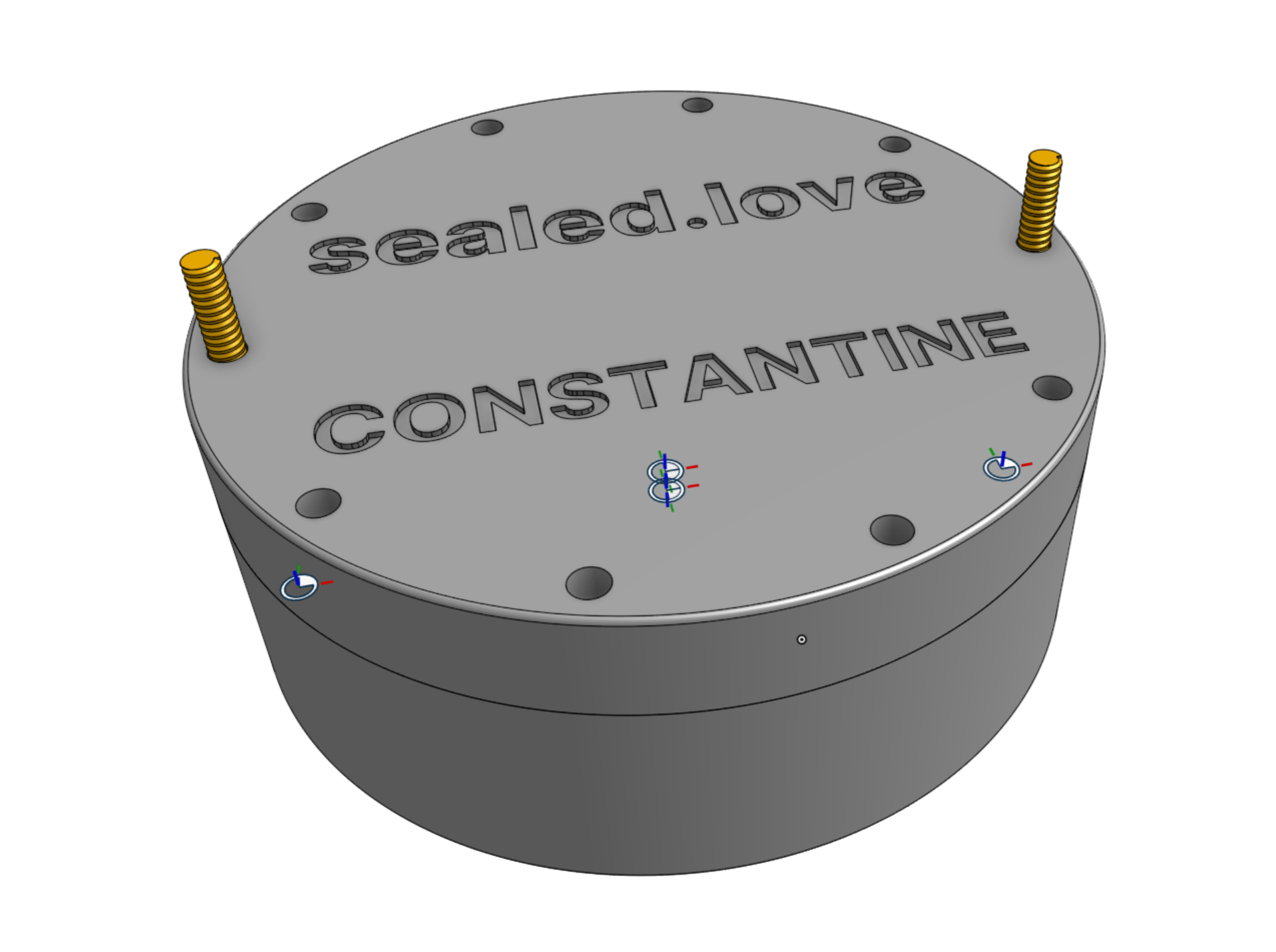

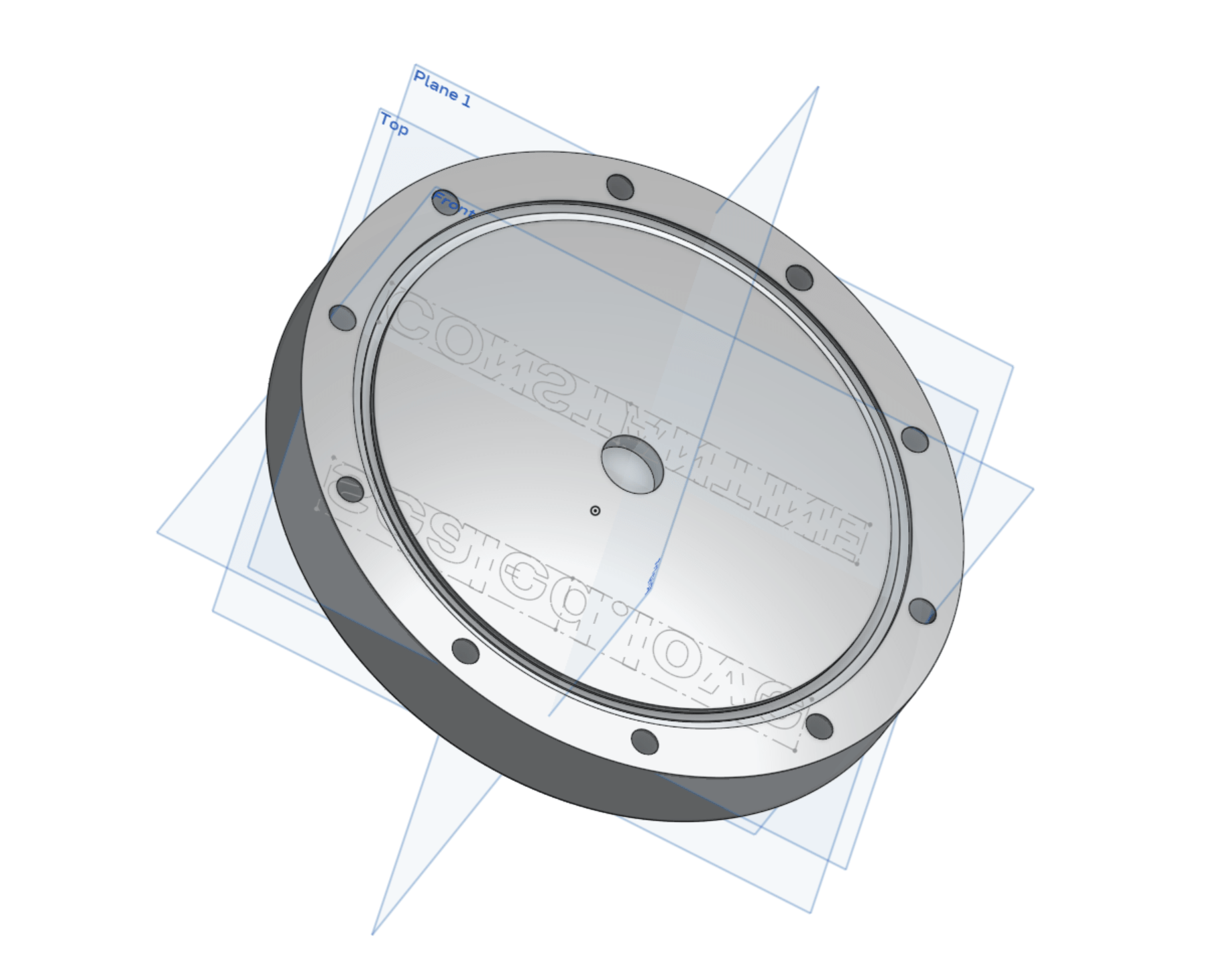

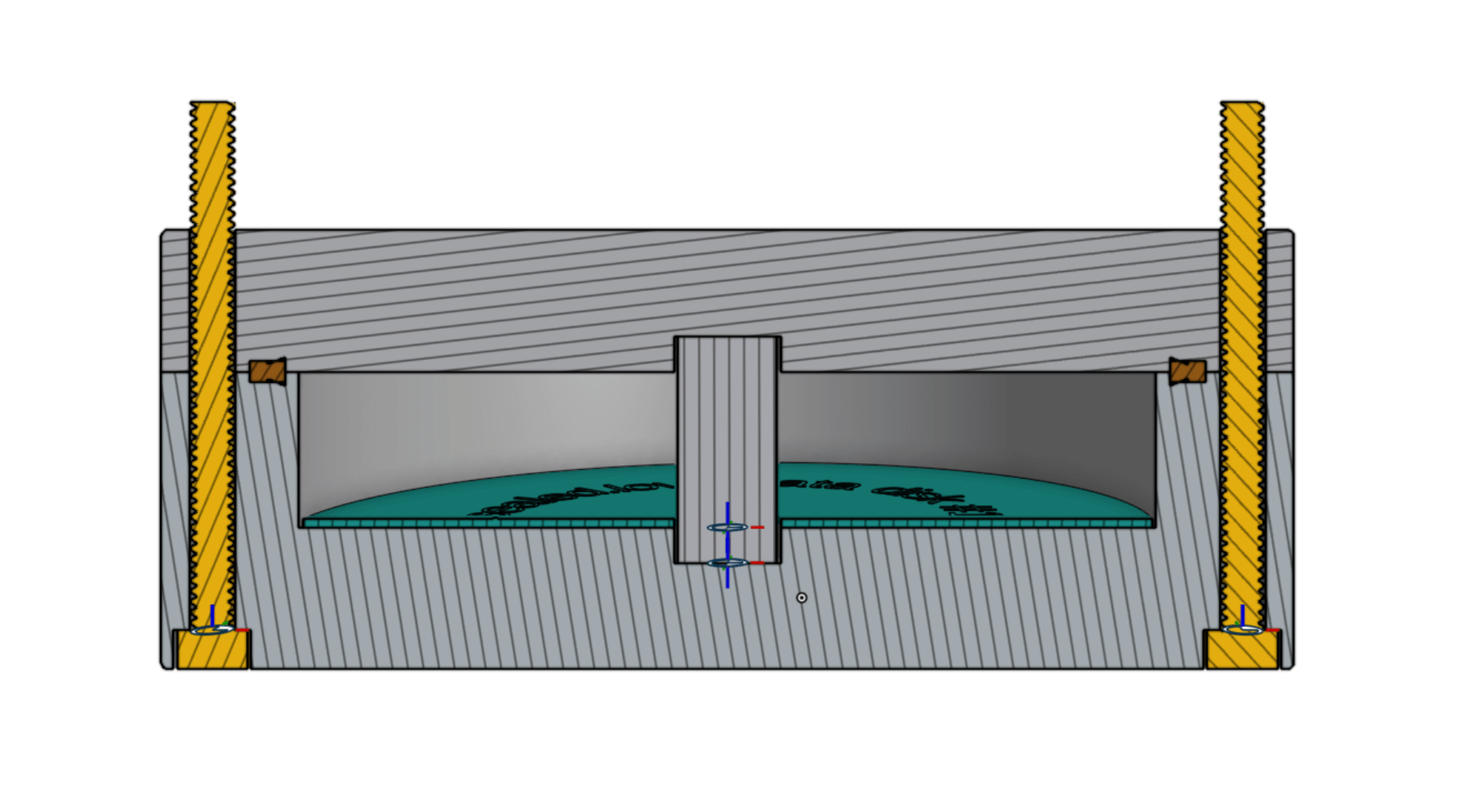

Shape: cylindrical vault made from stainless steel AISI 316L

-

Wall thickness: 20 mm for corrosion resistance and long-term strength

-

Two parts: main body and lid

-

Hermetic seal: a 5 x 3 mm copper gasket sits between body and lid. When the lid is tightened, the copper deforms and creates a tight, reliable seal.

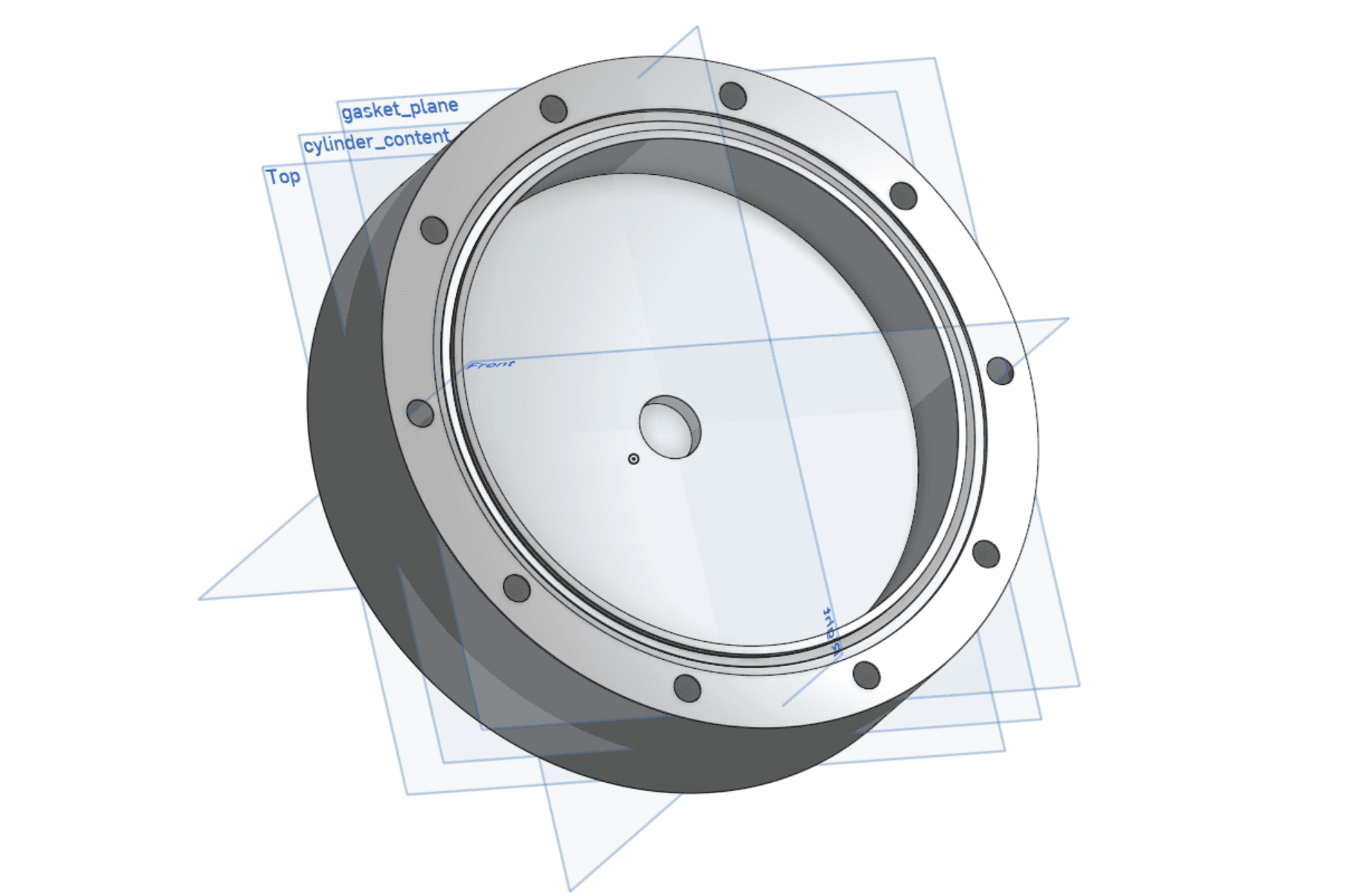

See the images included with this post:

-

assembly_with_lid.png – full 3D render of the capsule

-

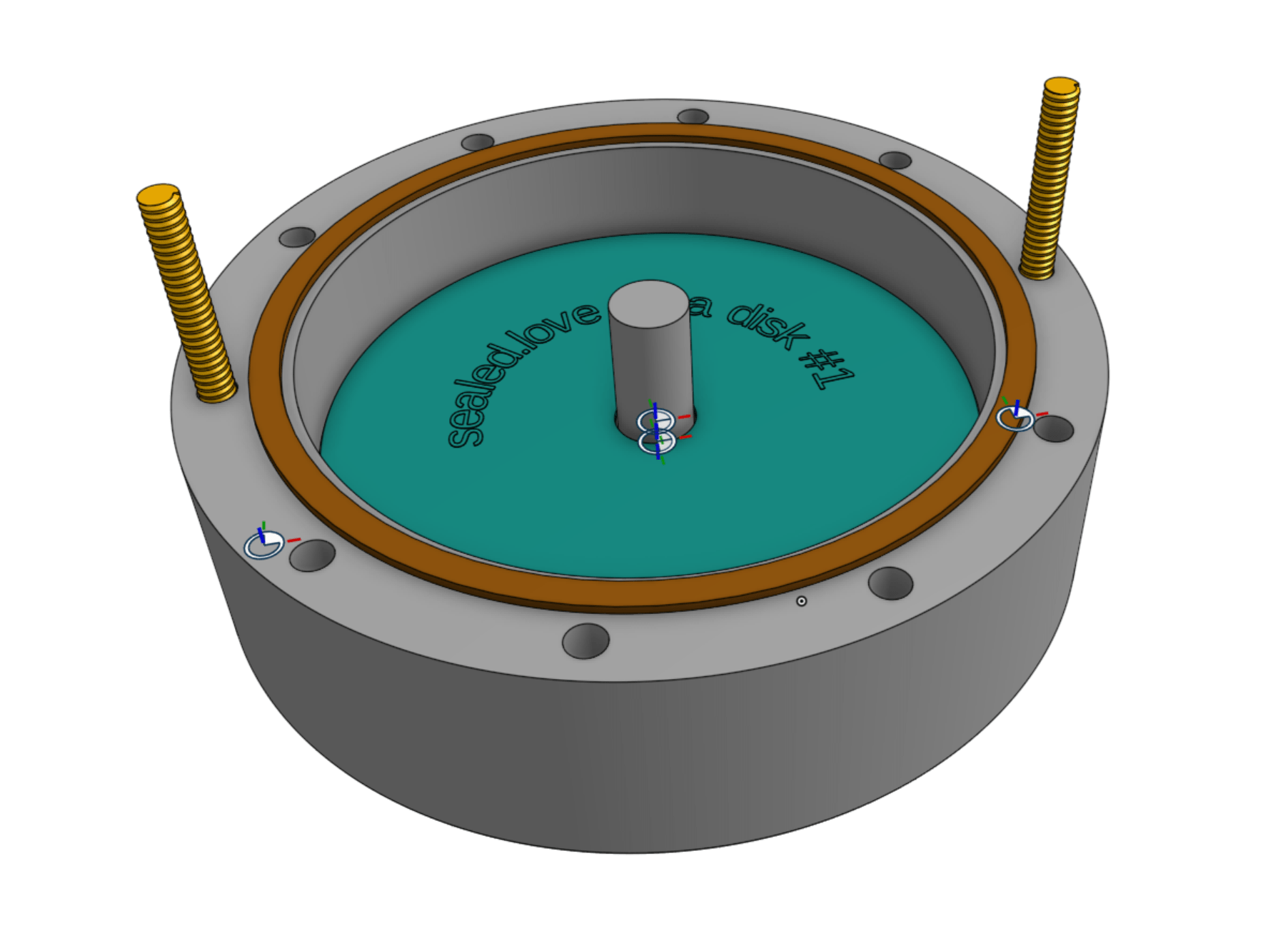

assembly_without_lid.png – body without lid, showing M-Disc stack and how parts fit

-

cylinder_body.png – main body render

-

cylinder_lid.png – lid render

-

section.png – front section view of the capsule

Inside the capsule

-

Media: M-Discs, chosen for their archival stability and very long tested lifespan

-

Mounting: the discs sit on a fixed stainless steel rod

-

Isolation: 1 mm Teflon spacers keep each disc away from direct contact with metal, preventing scratches and bending

-

Humidity control: silica gel inside the capsule

-

Seal: the deformed copper gasket blocks moisture and air, protecting against oxidation and biological activity

Layered protection outside the capsule

-

Wrap the steel capsule in HDPE foil, 2 cm thick, one or two layers depending on the site.

-

Place it inside a ceramic vessel with 5 cm walls, and backfill the space around the capsule with sand.

-

Seal the ceramic vessel and bury it.

This stack reduces temperature swings, disperses pressure, and shields the capsule from the environment for the long haul.

Why this approach

Every material and dimension is selected to trade short-term convenience for long-term reliability. Stainless steel 316L resists corrosion and keeps mechanical integrity over time. Copper is soft enough to flow and form a durable seal. HDPE, ceramic, and sand provide an extra passive barrier. The goal is simple: that someone far in the future can open the capsule and find your story intact.

Where we are now

-

Status: active prototyping

-

Changing things daily based on tests and fit checks

-

Next steps: machining the parts, verifying the gasket crush, confirming internal tolerances for the M-Disc stack, and documenting everything publicly

I’ll keep posting pictures from the shop floor, assembly tests, and any design tweaks. This is an open-source, free project. I’m all in on doing this right, with care and transparency.

If you have questions or ideas, reach out. I’m listening, building, and sharing as we go. Together, we’re creating something that can outlast us.